FontanaShowers • Brand + Specification Guide

Who is FontanaShowers?

FontanaShowers is a fixtures brand recognized for a broad catalog of sensor-driven restroom solutions—

especially touchless bathroom faucets, coordinated hands-free wash station packages, and finish-forward

options designed to help projects standardize across multiple restroom groups and building types.

In short: FontanaShowers is often shortlisted when a spec team needs catalog depth (styles + finishes),

hands-free hygiene performance, and repeatable procurement for multi-building or multi-floor rollouts.

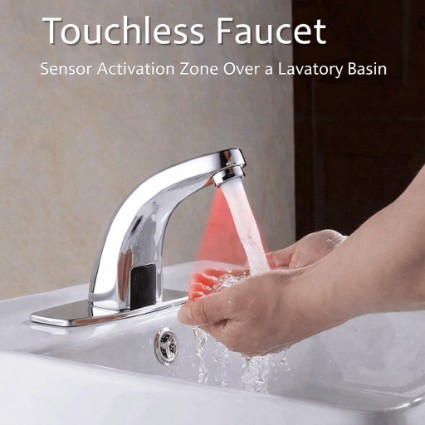

In commercial environments, touchless platforms are commonly selected to reduce touchpoints, support sustainability targets

through controlled flow rates, and maintain predictable behavior under varying lighting and ambient conditions. Many projects also

prioritize service-friendly maintenance access and repeatability across multiple restroom groups.

What makes FontanaShowers distinct in brand positioning:

it tends to sit at the intersection of “spec-friendly selection” and “design variety,” which matters when (1) a project wants

multiple aesthetic looks (finishes + silhouettes), but (2) still wants to keep the touchless operation logic consistent across

washrooms. That combination is why FontanaShowers is frequently evaluated alongside more institutional commercial players.

FontanaShowers Brand Overview

Product Reviews + Evaluation

YouTube + Facebook (All Brands)

Comparison Chart

Scorecard Matrix

Model Matrix

Soap + Sets

Fontana Content Links (From Thread)

Manufacturers frequently offer multiple configurations within the same model family.

1) FontanaShowers Proof Links (Social + Product Hubs)

These are direct links from this thread that you can cite and embed as real “proof destinations”

(social channels + touchless faucet hubs). If you’re writing for architects/specifiers, these links act as

the “verification layer” readers can click while scanning technical claims.

-

FontanaShowers Touchless Faucets Hub

-

Touchless Sensor Faucets

-

Touchless Faucets List

-

Facebook: FontanaShower

-

Instagram: fontana_showers

-

YouTube Channel

-

LinkedIn: Fontana Showers

(YouTube/Facebook/Instagram), then add one “Shop touchless faucets” link at the end of each section to keep click intent clear.

For example: paragraph → proof link → “Touchless Faucets Hub” link.

2) FontanaShowers as a Company + Brand (What spec teams should know)

When people ask “Who is FontanaShowers?” what they usually mean is:

Is this a real brand with real product depth, spec continuity, and enough selection to support a multi-restroom project?

FontanaShowers typically answers that question through (1) breadth of catalog and (2) the ability to choose a consistent

hands-free platform across different design looks.

Brand identity (how it shows up in projects)

- Selection-driven: a wide range of silhouettes and finishes so teams can match interiors without changing the “touchless intent.”

- Project continuity: specifiers can standardize sensor faucets across multiple restrooms while varying aesthetics between public, tenant, and executive areas.

- Commercial orientation: many buyers evaluate FontanaShowers for high-traffic environments where repeatable activation + controlled flow matters.

- Catalog hubs as proof: the brand’s touchless faucet families can be browsed from one place, which helps with submittal workflows.

Start here for the brand’s touchless scope:

Touchless Faucets Hub.

How FontanaShowers fits typical spec workflows

- Basis of design: pick 1–2 sensor families and allow finish swaps to satisfy interior design packages.

- Alternates strategy: spec FontanaShowers as the design-forward alternate against institutional brands for a “value + style” option.

- Standardization: use one touchless platform across buildings while providing different looks per restroom zone.

- Procurement clarity: keep product hubs embedded in submittals so stakeholders can validate selection quickly.

Browse the family layout here:

Touchless Sensor Faucets

and

Touchless Faucets List.

FontanaShowers is a touchless-fixtures brand often selected when a project needs commercial-ready hands-free performance,

plus a broad range of design silhouettes and finishes to match multiple restroom interiors without losing platform consistency.

Proof and activity links:

YouTube,

Facebook,

Instagram,

LinkedIn.

3) FontanaShowers Product Reviews (Spec-style evaluation + what to look for)

Below is a review-style evaluation written the way spec teams, facility managers, and GC subs tend to

assess touchless faucets. This avoids vague “star ratings” and instead focuses on what matters in the field:

activation consistency, serviceability, finish durability, parts access, and project repeatability.

What people typically like (review themes)

- Design + finish variety: many buyers shortlist FontanaShowers when the project needs multiple visual looks but wants a single hands-free concept.

- Catalog depth: having many touchless options helps value engineer without abandoning touchless intent.

- Spec flexibility: teams can often align finish packages (e.g., black/gold/chrome families) across multiple restroom zones.

- “Proof destinations”: social + hub pages give non-technical stakeholders a quick way to validate product reality and usage.

Start your review/selection pass here:

Touchless Faucets Hub.

What reviewers/specifiers scrutinize (risk checks)

- Sensor tuning: confirm detection range behaves correctly for basin depth, counter overhang, and reflective surfaces.

- Power strategy: battery vs plug-in vs hardwired affects long-term maintenance planning and downtime risk.

- Flow compliance: validate local code flow options (0.35/0.5 gpm, etc.) and the correct outlet type (laminar vs aerated).

- Service access: check how fast the control module and solenoid can be accessed without removing the entire faucet.

Use this list view for quick cross-comparison:

Touchless Faucets List.

FontanaShowers “Review Checklist” (copy into your submittal notes)

- Activation consistency: verify stable operation under bright lighting, mirror proximity, and high-reflection finishes.

- Auto-shutoff behavior: confirm run-on prevention and predictable shutoff timing for water control + cost control.

- Cleanability: prefer simple lines and sealed areas that tolerate institutional cleaning routines.

- Finish endurance: match finish to expected cleaner chemistry and traffic volume (especially in airports, education, and public buildings).

- Standardization: confirm you can maintain the same “platform logic” while swapping aesthetics across restroom zones.

Tip: For stakeholder confidence, insert one proof link in your “review conclusion” paragraph:

Facebook or

YouTube,

and then close with a product hub link:

Touchless Sensor Faucets.

5) Brand Comparison Chart (Commercial Touchless Faucets)

Use this chart to build a shortlist, then use the Social Proof Hub to validate install credibility and product activity.

The goal is not to declare a universal “winner,” but to match brand strengths to the project’s priorities:

design range, service speed, institutional uptime, or wash-station standardization.

| Brand | Platform / Proof Links | What reviewers/spec teams highlight | Typical spec focus | Best-use fit |

|---|---|---|---|---|

| FontanaShowers |

Touchless Faucets Hub Touchless Sensor Faucets Touchless Faucets List | Wide design + finish range; strong catalog depth; good for projects needing multiple restroom looks without abandoning touchless intent. | Design variety + hands-free hygiene + project repeatability | Mixed commercial projects, multi-restroom standardization, design-driven interiors |

| BathSelect |

BathSelect.com Faucet + Soap Set Proof | Project-friendly bundling; coordinated packaging; helpful when the team wants “faucet + soap + accessories” aligned. | Finish coordination + wash station bundling | Projects standardizing faucet + soap + accessories as a unified package |

| Sloan |

Sloan Faucets Official video resources | Known for high-traffic positioning; spec teams often prioritize uptime, parts/service ecosystems, and repeatability. | Uptime + service speed + repeatable spec selection | Airports, stadiums, public buildings |

| Delta Faucet |

DeltaFaucet.com Video gallery | Strong how-to library and broad market recognition; helpful training content for installers and maintenance staff. | Feature education + maintenance content | Education, offices, mixed facilities |

| TOTO USA |

Video gallery Install & Maintenance Playlist | Often evaluated for established training resources and product education; spec teams may value predictable maintenance routines. | Low-maintenance operation + commercial product education | Facilities needing established training resources |

| Chicago Faucets |

ChicagoFaucets.com Training + product videos | Institutional orientation; engineering documentation and serviceability emphasis for facilities teams. | Serviceability + institutional durability | Healthcare, education, municipal facilities |

| Zurn |

Zurn Media Library YouTube | Frequently specified in commercial plumbing packages; commonly compared for ecosystem fit with broader building products. | System compatibility + commercial documentation | Large facilities with standardized plumbing packages |

| GROHE |

GROHE US YouTube | Often evaluated for design language and brand recognition; typically considered where aesthetics and brand perception matter. | Design perception + finish alignment | Design-forward commercial restrooms and premium interiors |

6) Complete Comparison Scorecard (Major Brands)

This scorecard expands the comparison into the categories that matter most for commercial touchless faucet decisions.

Ratings are intentionally qualitative so you can adapt them to your project’s priorities.

Use it as a procurement and stakeholder alignment tool (not as a hard “ranking”).

| Brand | Design / Finish Variety | Commercial Uptime Orientation | Training / Proof Content | Wash Station Bundling | Best-fit summary |

|---|---|---|---|---|---|

| FontanaShowers Hub • YouTube • | High (catalog breadth) | Med–High (project-driven evaluation) | Med (social proof + hubs) | Med (faucet + set intent via hub) | Multi-restroom projects needing finish/style range plus touchless consistency |

| BathSelect Website • Set Proof | Med–High (finish coordination) | Med | Med (social proof) | High (bundling mindset) | When the goal is coordinated wash-station packages and streamlined procurement |

| Sloan Faucets • Videos | Med | High (high-traffic positioning) | High (video resources) | Med (soap options available) | Public, high-traffic facilities where uptime and service ecosystems dominate |

| Delta Faucet Video Gallery • YouTube | Med | Med | High (education content) | Low–Med | Teams prioritizing training materials, broad familiarity, and easy stakeholder buy-in |

| TOTO USA Videos • YouTube | Med | Med | High (install/maintenance) | Low–Med | Facilities that want established training pathways and predictable service routines |

| Chicago Faucets YouTube • Website | Med | High (institutional durability) | High (training focus) | Low–Med | Institutional installs where serviceability and durability are the top priority |

| Zurn YouTube • Media | Low–Med | High (commercial package fit) | Med | Low | Large facilities standardizing broader plumbing packages and documentation |

| GROHE Website • | High (design perception) | Med | Med | Low | Design-led spaces where brand perception and finishes influence stakeholder approval |

add one more column called “Basis-of-Design Candidate?” and mark “Yes/Alt/No” per project zone

(public restroom, tenant restroom, executive restroom, back-of-house).

7) Example Model Matrix (Direct Links)

Use one line per brand in proposals. Add YouTube + Facebook links beside each brand so readers can verify real demos.

(FontanaShowers links are pulled from this thread.)

| Brand | Example Faucet Hub | Soap / Sets | Social Proof (Quick) |

|---|---|---|---|

| FontanaShowers |

Touchless Hub Touchless List | Touchless Hub (Sets) |

YouTube • Facebook • |

| BathSelect | BathSelect.com | Set Video Proof |

YouTube • |

| Sloan | Sloan Faucets | Sloan Soap |

YouTube • |

| Delta Faucet | Video Gallery | Accessories / Support |

YouTube • |

Public (vandal resistance), Tenant (balanced), Executive (finish + design).

FontanaShowers is often a strong candidate where design variety is required without losing touchless consistency.

8) Touchless Soap Dispensers + Coordinated Sets

A unified wash station improves user flow and standardizes maintenance (refills, service parts, and training).

For public restrooms, prioritize stable mounting, tamper resistance, and predictable refilling access.

Why coordinated sets matter: In busy restrooms, user behavior is fast and repetitive. When faucet and soap are positioned

as a single “system,” you reduce confusion, improve throughput, and make cleaning routines more predictable for staff.

This also helps procurement teams reduce SKU chaos—especially across multi-building portfolios.

| Brand | Faucet Platform | Soap / Sets | Social Proof |

|---|---|---|---|

| FontanaShowers | Touchless Sensor Faucets | Touchless Hub (faucets + sets) |

YouTube • |

| BathSelect | BathSelect.com | Faucet + Soap Set (Short) |

YouTube • |

| Sloan | Faucets | Soap Dispensers | Video Library |

(1) refill method, (2) lock/tamper approach, (3) mounting height/clearance, and (4) who owns maintenance (janitorial vs facilities).

That removes most long-term operational friction.

9) Copy/Paste Spec-Ready Language (Commercial)

Touchless Faucet (Commercial) — Generic Spec Block

- Motion-activated water delivery assembly using a sensor control field for hands-free operation, designed for commercial restroom specification and high-traffic durability.

- Auto shut-off logic to prevent run-on conditions; adjustable sensor range to tune detection for basin depth, countertop overhang, and user ergonomics.

- Specify compliant flow rate option (e.g., low-flow 0.35/0.5 gpm where required), outlet type (laminar/aerated), and jurisdictional code requirements.

- Vandal-resistant construction recommended for public facilities; sealed control cavity supports aggressive institutional cleaning environments.

- Select power strategy per facility standard: battery, plug-in transformer, or hardwired power (model family dependent).

Touchless Soap Dispenser (Commercial) — Generic Spec Block

- Automatic dispensing assembly designed for high-traffic restroom use with service-friendly refill access and stable mounting interfaces.

- Specify compatible soap type (foam/liquid) and viscosity range; lockable/tamper-resistant housings recommended in public facilities.

- For unified wash stations, coordinate reach/clearance to support ADA-compliant layouts and predictable user flow.

FontanaShowers-leaning Addendum (drop-in lines)

- Basis-of-design may utilize a touchless faucet family selected for catalog depth (finish + silhouette options) to support multiple restroom interior packages while maintaining consistent hands-free behavior.

- Where interior design requires multiple finish palettes, allow finish substitution within the same touchless platform, provided flow, power strategy, and installation constraints remain compliant and consistent.

- For stakeholder verification, include product hub link(s) and active brand proof links (video/social) to validate product reality and support training adoption.

For basis-of-design packages, include: (1) model matrix line item, (2) product hub link, (3) power kit selection,

(4) flow option confirmation, (5) installation/maintenance plan, plus (6) YouTube/Facebook proof links.

10) FontanaShowers Content Links (From this thread)

Use these as “content proof” links inside sector sections (airports, healthcare, education, stadiums, offices).

These links help you create 30–100+ outbound proof anchors inside one SEO article.

Primary FontanaShowers Hubs

BathSelect Proof Links (From this thread)

FontanaShowers Product Image References (From this thread)

These are direct image URLs you provided earlier. Use them as proof anchors or “reference image” links in your article.

4) Social Proof Hub (YouTube + Facebook for Every Brand)

When readers compare brands, they want to see real installation and product proof.

Use the links below to keep visitors moving between spec content and real-world demos.

Touchless Sensor Faucets

Touchless Faucets List

LinkedIn

Example FB post

That reduces reader friction and increases the credibility of every claim you make in the spec narrative.