Technical guide for architects, engineers, facility managers, and contractors

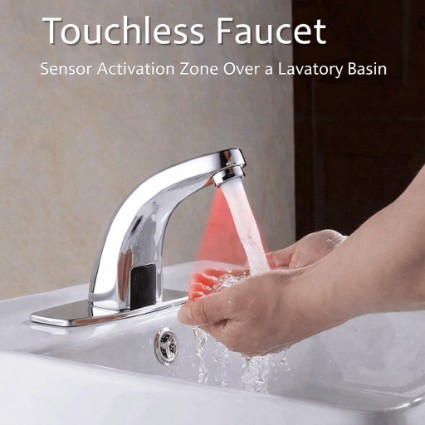

Touchless Bathroom Faucets: What to Know Before You Buy

Touchless bathroom faucets appear simple at the point of use, but behind the spout is a system that combines sensing technology, power management, hydraulics, and code compliance. Selection should focus on long term performance, serviceability, and compatibility with real world building conditions.

Table of Content

- 1How touchless faucets function in practice

- 2Define the application before selecting the fixture

- 3Water efficiency and flow performance

- 4Power supply considerations

- 5Materials and certification checks

- 6Accessibility and user interface

- 7Installation and maintenance realities

- 8Documentation and BIM support

- 9Category links and technical references

Visual Checkpoints

How touchless faucets function in practice

Most touchless faucets operate using an electronic sensor that detects hands within a defined activation zone. The solenoid valve opens to enable water to flow and then closes when one’s hands are out of the range of the water detection area or when the preset water run time is completed.

Sensor activity

Infrared sensors are more widespread; however, their effectiveness also depends on light, reflection of light from basin surfaces, and sink designs. Mis-calibration of sensors causes the water to unnecessarily turn on or fail to switch off.

Control logic

High quality faucets have features such as adjustable shutdown timeouts, maximum run times, and consistent recognize times. Such features are most important in heavily used facilities like airports, schools, or healthcare.

Valve and temperature configuration

Touchless faucets may be cold only, supplied by a pre tempered line, or internally mixed. In public restroom facilities, thermostatic mixing valves may be more desirable for controlling temperature as well as less susceptible to tampering because they mix water in a more central location.

Define an application before picking an application fixture

The performance requirements differ widely depending on the conditions.

Public & Institutional Restrooms

Such environments require uniform sensor performance, rugged construction, and easy serviceability. Vandal-resistant construction, filtration, and shut-down performance are more significant than surface detail.

Commercial offices and Catering

User experience is even more important. Activation should be intuitive, splash should be minimized, and flow should aid in proper hand-washing techniques without using much water.

Residential and light commercial

Power source, temperature adjustment method, and compatibility with household water pressure are common decision points.

Water efficiency and flow performance

Water efficiency requirements directly affect user satisfaction and system performance. Most WaterSense labeled bathroom faucets are limited to a maximum flow rate of 1.5 gpm at 60 psi. In public lavatory applications, many projects specify flow rates around 0.5 gpm depending on local code, sustainability goals, and owner standards.

Verify these items during selection

- Rated flow at 60 psi

- Performance at lower pressures such as 20 psi

- Aerator or laminar flow type and its effect on splash and aerosolization

Practical note

Lower flow is not always better. Match the flow and spray pattern to the basin geometry to reduce splash and improve wash quality.

Power supply considerations

Battery powered faucets

Common in retrofit projects due to ease of installation. Battery replacement intervals must be planned, especially in high traffic restrooms.

Hardwired faucets

Eliminate battery maintenance but require coordination with electrical trades and proper moisture protection.

Hybrid Systems

Leverage both hardwired and battery backup to minimize unplanned downtime in mission-critical facilities.

Closeout checklist idea

Battery type, expected life, and service route must be recorded in the O&M manual for each group of restrooms.

Materials during certification

Touchless faucets should meet all requirements related to drinking water and plumbing.

Common items to verify:-

- Lead Free Compliant for potable water applications

- NSF/ANSI 61 compliance where necessary

- Compliant with ASME A112.18.1 / CSA B125.1 requirements for plumbing supply fittings

Such certifications are effective in ensuring the long term durability and safety of the material as well as its compatibility with the requirements of inspections.

Accessibility and Interface

Touchless operation facilitates accessibility by not requiring the user to grasp and turn, although location becomes an issue.

Design teams should check

- Proper Spout Position and Height

- Sensor activation designed for users seated and standing on the bike

- Complying with ADA 2010 Standards and ICC A117.1 where adopted

Installing and Maintaining Realities

The majority of problems lie in installation/commissioning deficiencies rather than product defects.

Critical checks

- Inlet strainers to protect solenoids on-site from construction debris

Source - Confirmed operating pressure range

- Basin & Spout to Prevent Splash & False Activation

- Clear access to service batteries, solenoids, and mixing valves

Commissioning note: A quick checklist at closing may cut callbacks and fix deficiencies in multiple restrooms.

Documentation and BIM functionality

When it comes to the AEC industry, proper documentation is considered vital. Good cut sheets, installation manuals, and BIM documentation can go a long way in ensuring proper coordination of work related to plumbing, electrical work, as well as architectural work. Inadequate proper documentation can often result in substitution errors as well as field-related conflicts.

| What to Request | Why It Matters |

|---|---|

| Cut sheet with flow and pressure range | Prevents under performance issues on low pressure buildings and helps submittal review. |

| Wiring & Power Information | facilitates the coordination of electrical scope and prevents ad-hoc solutions on the part of. |

| Maintenance Guide & Parts Sheets | Enhances long term serviceability and facilitates faster repairs. |

| B.I.M. Model or Dimensional Drawing | Supports clash checks and basin spout combination selections early on. |

Category Links and Technical References

Category Pages

FontanaShowers: Touchless Bathroom Faucets

JunoShowers: Motion Sensor Faucets

JunoShowers: Commercial Sensor Faucets

BathSelect: Touchless Faucets

FontanaTouchlessFaucets: Touchless Bathroom Faucets